The Chemical Industry & IOT: Transforming Operations, Gaining Insights & Shareholder Value

Chemical businesses are rapidly adopting new technologies for digital transformation.

The integration of IoT will supercharge the ROI by enhancing operational efficiency and yielding bested outcomes. Like JIT, LEAN and SIGNMA, IOT MUST be an integrated part of the value chain or, COGS and many other measures will fall short of target.

In plants, IoT monitors availability safety equipment, tools, inventory, capacity and performance in real-time. By utilizing sensors to gather data on ALL equipment such as leak detectors, fans, and pumps. In this frame, companies can proactively and PREDICTIVELY identify potential issues before they occur. This proactive approach reduces costs, minimizes downtime, and increases productivity.

According to Allied Market Research, the global IoT industry is expected to reach $193.9B by 2031, at a CAGR of 13.3%.

Use Cases of IoT in Chemical Industry

The core applications are diverse and encompass various aspects of operations, safety, and efficiency...

Regulatory Compliance Chemical is highly regulated. Government bodies continuously issue new rules and procedures, and compliance is mandatory compounded by a global footprint. One way to achieve compliance is to digitize chemical batch records traditionally maintained on paper. Digitizing batch records makes them available, searchable allowing for compliance in the digital age.

- Improved compliance

- Increased efficiency

- Reduced costs

- Improved quality

- Searchability

With IoT chemical companies can integrate with factory data sources providing dashboards and reports. Information and prediction that provides for greater effectiveness and compliance.

Product Traceability Chemical manufacturers must have adequate controls over the process, quality, and delivery of their products to maximize margin. It requires hyper-management and a frictionless, preventive and predictive environment with emphasis maintaining the quality and safety standards of the end product.

However, they often overlook “#outboundtraceability” (the process of tracking raw materials as they are transformed into a sellable product aka. the value add) Outbound traceability allows for building better relationships with customers providing transparency throughout the value chain and IoT achieves this end result. It brings important data to a single location, ensuring that the data is up-to-date and scalable across multiple locations. This data can be used to create quality dashboards and audit trails, which can provide complete process transparency.

Remote Monitoring for Safety IoT is a popular tool in the chemical industry for remote monitoring of processes and operations. This technology allows companies to monitor their plants and equipment from anywhere in the world, which can help to reduce the risk of accidents and improve efficiency. IoT sensors can be used to monitor the condition of assets, such as pumps, valves, and reactors. This data can be used to identify potential problems before they cause an accident or a breakdown. (air quality control) Sensors can also be used to create smart tags that can be worn by workers. These tags can alert workers to the presence of dangerous substances, which can help to prevent exposure.

IoT-Advanced Analytics is used to improve forecast accuracy, which can lead to improvements in supply, LEAN, SIGNMA sales and operations planning and KPIs

In the case of natural disasters or rail or road blocks automatic rerouting of shipments can be performed to ensure supply, meeting customer commitments, while minimizing associated delay costs.

Another opportunity is to optimize the use of transportation assets and related costs. Transporting chemicals requires special equipment and complex compliance requirements, which often leads to empty backhauls.

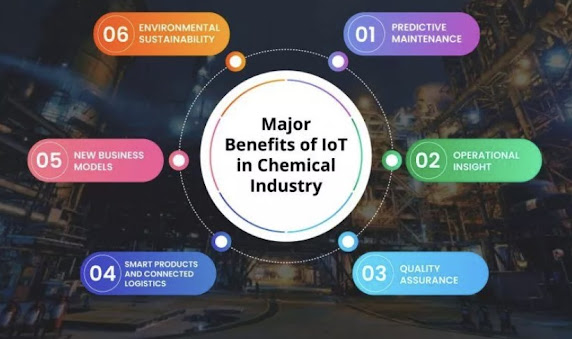

The Internet of Things (IoT) offers numerous benefits to the chemical industry, which transforms operations and enables enhanced efficiency, productivity, and safety.

Predictive Maintenance Modern assets in the chemical industry such as chemical reactors integrated embedded software and analytics to assess their condition. These assets communicate signals about their performance and health which facilitates the prediction of potential malfunctions and maintenance requirements. Augmented reality, which offers 3D visualization of assets in a spatial context enhances the maintenance practices from the perspective of services.

Operational Insight Chemical companies generate vast amounts of data during the manufacturing process, yet only a fraction of it is utilized to improve decision-making and add value. By integrating and analyzing all available data in real-time and consolidating the results for intelligent decision-making, businesses can enhance operational, safety, and environmental performance.

Quality Assurance Rapid analysis of large volumes of data can greatly enhance quality assurance processes. Instead of focusing solely on the handful of batches, many chemical businesses can now analyse tens of thousands of batch results across their entire operations. This broader dataset facilitates the adjustment of operating conditions and improved quality management.

Smart Products and Connected Logistics In the intricate and highly regulated global business environment, integrating the supply chain is crucial. Data from sensors embedded in product packaging or transportation assets can assist in tracking and tracing product location, condition, and authenticity. I.e RFID tags can generate alerts or signals when temperature or moisture levels deviate from acceptable ranges or provide evidence of product counterfeiting during shipment. Furthermore, sensors can facilitate container tracking and asset location to prevent loss.

New Business Models Nowadays, farmers want to achieve higher yields while using fewer chemicals in a precise manner, often referred to as “precision farming.” This approach is achievable through the ecosystem of farmers, agribusiness suppliers, equipment manufacturers, traders, and technology providers. For supporting precision farming, these stakeholders require a secure, and data-enabled platform for accessing and sharing information. Sensors play a pivotal role in capturing and transmitting information such as local weather data, GPS data, or specific soil conditions including fertilizer and crop protection levels, contributing to the success of these innovative business models.

Environmental Sustainability IoT enables better control over energy consumption, waste management, and emissions. By monitoring and optimising resource usage, chemical-based enterprises can reduce their carbon footprint, adhere to environmental regulations, and improve sustainability practices. IoT-driven insights can help identify energy-efficient alternatives, optimize processes, and reduce waste generation.

Wrap Despite facing intense competitive pressures and strict safety and compliance regulations, the chemical industry has yet to fully harness the potential of IoT, which provides a valuable competitive advantage and SHAREHOLDER VALUE.

Open Ascension offers a comprehensive #IoT solution tailored for the chemical industry, enabling real-time monitoring, predictive maintenance, and process optimization. Our IoT-END TO END #solution combines advanced sensors, data analytics, and automation to enhance operational efficiency.

Comments

Post a Comment